Digital Factory

GH Turbine is built into an all-round digital factory, which identifies the necessary steps, builds modules and monitors various performance using an autonomous operation system, so as to improve safety and production efficiency, reduce human intervention and overall costs, and further reduce the impact on the environment.

Digital R&D

The digital R&D system covers the entire R&D process from demand, design, verification to final confirmation, significantly improving design efficiency and accuracy. In addition, the “digital twin” for the entire life cycle of gas turbines is under step-by-step building, so as to reduce the physical costs of product testing, manufacturing and maintenance.

R&D data runs through the entire life cycle of design, manufacturing, testing, and maintenance, and features good explicitness, standardization and systematization.

Digital Manufacturing

The fully integrated digital lean manufacturing management enables to achieve networked, digital, and paperless execution control. As all CNC equipment are networked, PLM, MES, DNC and other systems are integrated to achieve IoT interoperability in the manufacturing process of gas turbine.

The production efficiency is greatly improved, since the production schedule is controllable in real time, the quality data is complete and traceable, the process data structure is optimized.

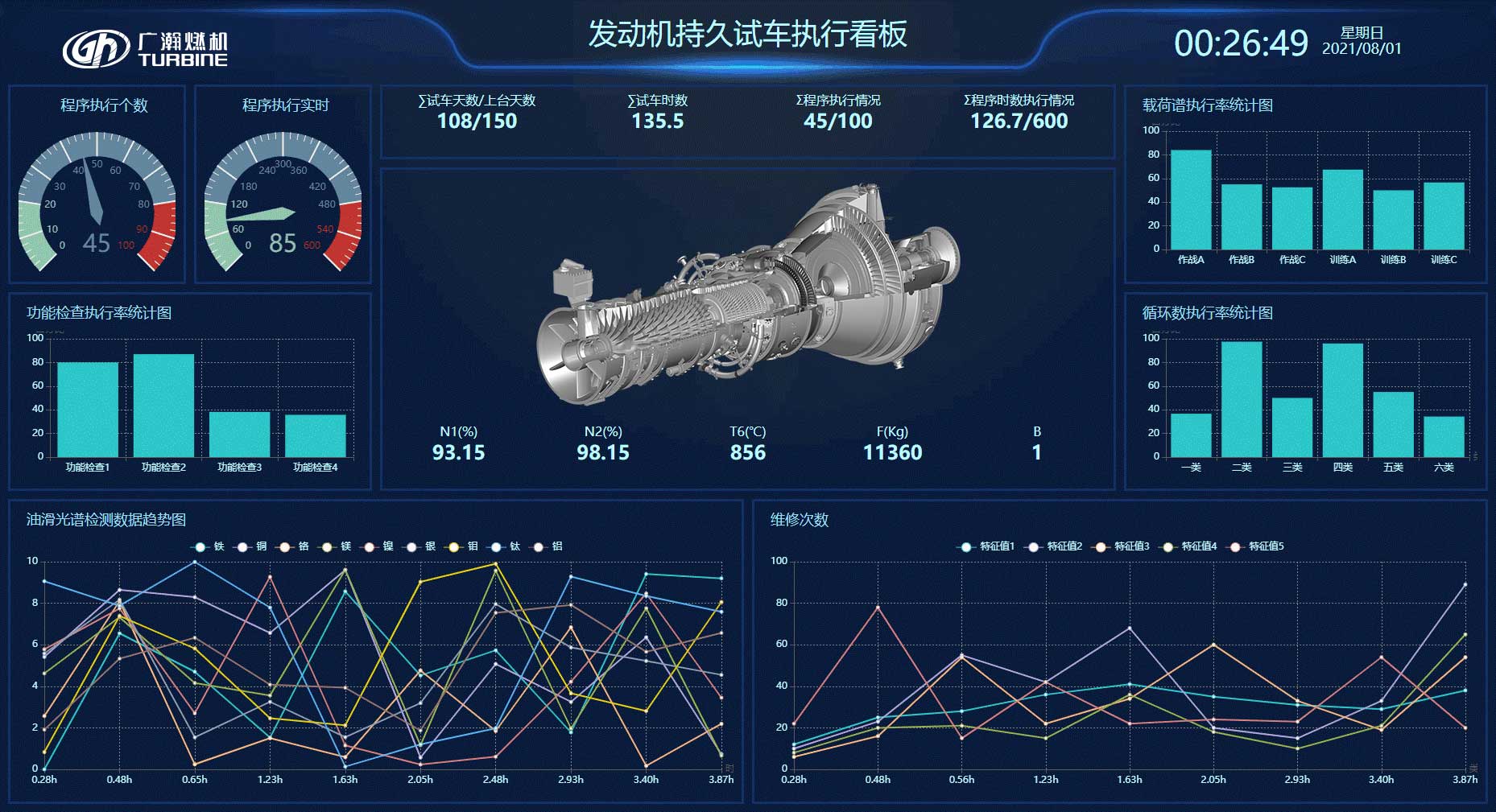

Digital Experiment

The digital experimental management and control platform puts the test benches for entire engine, components, subsystems, structural strength and other requirements under centralized management for gas turbine development. It conducts the performance analysis of test pieces using multiple data analysis algorithms to improve the efficiency of test data post-processing.

Intelligent interpretation technology provides feasibility and rationality data support to assist in optimizing design decisions.

Digital Services

With a full-parameter remote operation analysis, fault diagnosis, and expert support system, we provide digital services for customers in fields of offshore oil and gas exploitation, industrial power generation, and natural gas pipeline transportation. By means of health evaluation and trend prediction algorithms, the operation and maintenance costs of gas turbine units are significantly reduced, and the effective working time of gas turbine is extended.

With data operation status monitoring, fault prediction, fault diagnosis and risk assessment, we provide high-value decision support for customers.